Vacuum Freeze-drying Equipment

- SMARTCOLD

- DALIAN, CHINA

- 45 DAYS

- 1 SET PER WEEK

The freeze-drying is short for freeze dryer which is the most advanced food drying technology, and widely used in vegetable, fruit, meat , marine products, dairy products, soup and health care products and some other processing products.

Vacuum Freeze-drying Equipment Process Optimization

*Optimize the technical process according to the material quality and the requirements of customers.

*Provide operation management technical support for freeze-drying plant, like the quality assurance system, inspection method, health standard and so on.

*Ensure to keep nutrient in maximum, Keep original shape and color, shelf life is long, convenient to carry and eat.

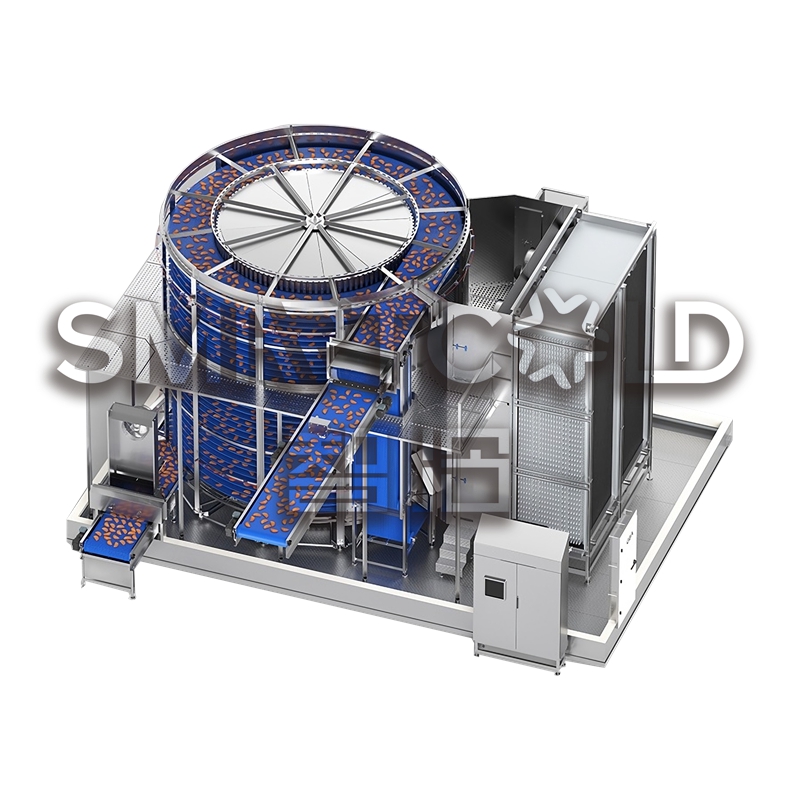

Product diversity, system high efficiency

*Solid freeze-drying engineering, achieves the multiple function of freeze-drying process for seasonality and diversity of products. Which enjoy the high production efficiency, time saving and energy consumption reduction.

*Fluid freeze-drying engineering effectively addresses the matters of uniformity of fluid material transportation and loading, avoid second pollution and cross contamination, and can achieve the CIP cleaning for the complete system.

*Functional products freeze-drying engineering could protect the active components in the material or avoid the aggregation of material particles.

Vacuum Freeze-drying Equipment Scientific And Reasonable Composition

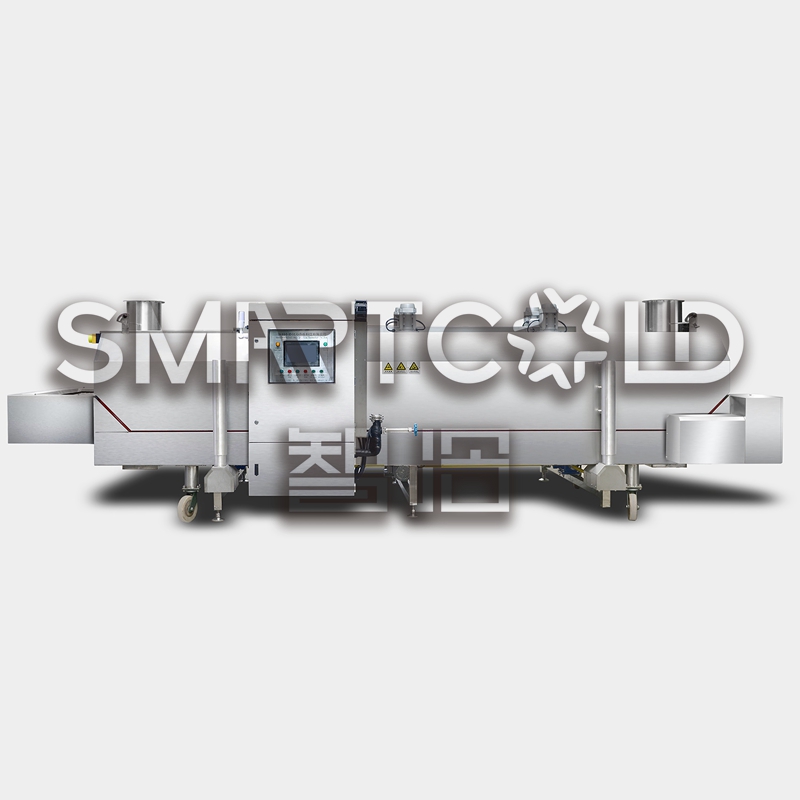

*The system consist of freeze-drying machine, vacuum system, heating system, refrigeration system, defrost system, transport system, pneumatic system and electric control system.

*Stainless steel drying bin shell is used which is hygiene and durable. Aluminum alloy heating plate and cold trap is anodizing on the surface.

*Double chamber door, and pneumatic translating chamber door is set at the feed end.

*Rear-mounted cold trap is hygiene and easy to maintain.

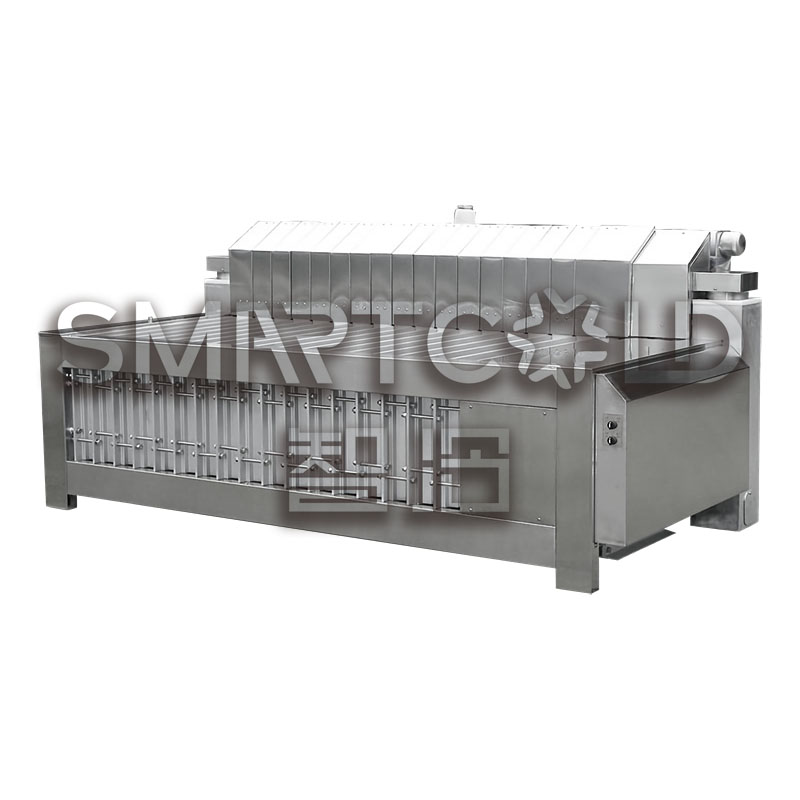

*Possess patented heat flow arrangement with characters of even temperature, precise temperature controlling and high efficiency heating.

*Innovative Aluminum plate evaporator has character of high efficient heat exchange. And the double cold trap capture water systems conform to the process state.

*The ground track or mounting track can be selected to transport the material, the newly style ground track with the character of flexibility, safety and convenient is recommended.

*The ammonia (R717) or Freon (R22. R404A or R507) are optional as the refrigerant for the refrigerating system.

*Provide the cleaning in position and automatic handling pallets device for the drying bin.

*Meet requirement of GMP.

Vacuum Freeze-drying Equipment Technology Parameter Table

| parameters | ZLD02 | ZLD5 | ZLD10 | ZLD25 | ZLD50 | ZLD75 | ZLD100 | ZLD125 | ZLD150 | ZLD200 | |

| Mode | |||||||||||

| Trays area | m2 | 0.25 | 5 | 10 | 25 | 50 | 75 | 100 | 125 | 150 | 200 |

| Largest capability of catching water | kg/h | 0.5 | 10 | 20 | 50 | 100 | 150 | 200 | 250 | 300 | 400 |

| Largest quantity of catching water | kg/time | 3 | 60 | 120 | 240 | 600 | 900 | 1200 | 1500 | 1800 | 2400 |

Heating plate working temperature | °C | 5 ~ 125 | |||||||||

Drying camber working pressure | Pa | 13~133Pa | |||||||||

| Ultimate vacuum of drying chamber | Pa | ≤10 | |||||||||

| Vacuum pumping time | min | ≤10 | ≤12 | ≤15 | |||||||

| Evaporative temperature of cold trap | °C | -50 ~ -30 | |||||||||

| Refrigeration capacity | kW | 0.4 | 8 | 16 | 32 | 80 | 120 | 160 | 200 | 240 | 320 |

| (0.7MPa) Maximum vapor con sumption | kg/h | 12 | 24 | 48 | 120 | 180 | 240 | 300 | 360 | 480 | |

| Installation power (Exclude refrigeration system) | kW | 2 | 8 | 15 | 30 | 55 | 70 | 80 | 95 | 105 | 120 |

Step 1, please tell us what model and quantity you need; Step 2, then we will make a Pl for you to confirm the order details; step 3, when we confirmed everything, can arrange the payment; step 4, finally we deliver the goods within the stipulated time....more

Notice: Undefined variable: seo_tags in /www/wwwroot/smartcold.tech/UserFiles/templates/nmoban16_2/product_info.php on line 121

Warning: Invalid argument supplied for foreach() in /www/wwwroot/smartcold.tech/UserFiles/templates/nmoban16_2/product_info.php on line 121